Alloy Analysis with Skyray XRF Spectrometers

Alloy verification is an important process for many businesses today in order to determine alloy composition and grade. Portable XRF Analyzers became the benchmark of Alloy and Metals analysis, providing business worldwide with fast and accurate way to control alloy grades, material mix-ups, quality assurance and product safety.

Skyray Instruments Alloy XRF Analyzers can be used for variety of alloy types including:- Carbon Steel- alloys from Iron(FE) and Carbon(C) with low percentages of Manganese (Mn), Silicon(Si) and Copper (Cu)

- Stainless Steel- corrosion resistant alloys containing Nickel(Ni), Chromium (Cr), Molybdenum (Mo), and Copper (Cu)

- Low Alloy Steel- high strength and hardness alloys containing Carbon(C), Manganese (Mn), Silicon(Si) , Nickel(Ni), Molybdenum (Mo), Boron(B), Vanadium(V), and Chromium (Cr)

- Tool Steel- high hardness alloys with resistance to abrasion and deformation carbon and alloy steels

- Aluminum Alloys- alloys made mostly from Aluminum(Al) mixed with Copper (Cu), Magnesium(Mg), Manganese (Mn), Silicon(Si), Tin(Sn)in and Zinc(Zn)

- Titanium Alloys- high tensile strength and toughness light weight alloys, able to withstand extreme temperatures

- Nickel Alloys- nickel chromium base alloys are used extensively in applications where heat resistance and/or corrosion resistance is required

- Magnesium Alloys –lightweight alloys made mostly from Magnesium(Mg) mixed with other elements including: Aluminum(Al) , Copper (Cu), Manganese (Mn), Silicon(Si), and Zinc(Zn)

- Copper Alloys- metal alloys with high resistance against corrosion that have Copper (Cu) as main component

- Zinc Alloys-galvanized alloys with high Copper content, Brass being the most popular Zinc alloy

- Precious Metals- alloys based on precious metals Gold(Au), Silver(Ag), and Platinum(Pt)

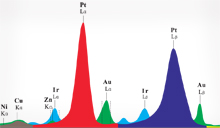

Skyray X-Ray Fluorescence Spectrometers are ideal instruments for fast and non-destructive alloy analysis and positive material identification(PMI). Multiple alloy analysis modes including quantitative analysis, qualitative analysis and multi-calibration methods. Fundamental parameter technology provides more analytical modes and Dynamic match function displays test results, sample numbers and matching information on the interface simultaneously. Our instruments come with complete alloy database in order to identify pure metals and different alloy grades. Accurate analysis of high & low alloy steel, stainless steel, tool steel, chromium/ molybdenum steel, nickel alloy, cobalt alloy, nickel/cobalt heat resistant alloy, titanium alloy, copper alloy , bronze, zinc alloy, tungsten alloy and others.

Why use a Skyray XRF Spectrometer for metal alloy analysis?- rapid analysis – results in seconds

- non-destructive analysis

- ppm to 99.99 % concentration range

- minimal or no sample preparation

- analysis software with large alloy database

- qualitative and quantitative analysis

Information about alloy grade of material is essential for professionals in many different industries in order to make important decisions on corrosion resistance, durability and material properties and ensuring the quality and safety of the final product.

Related Products

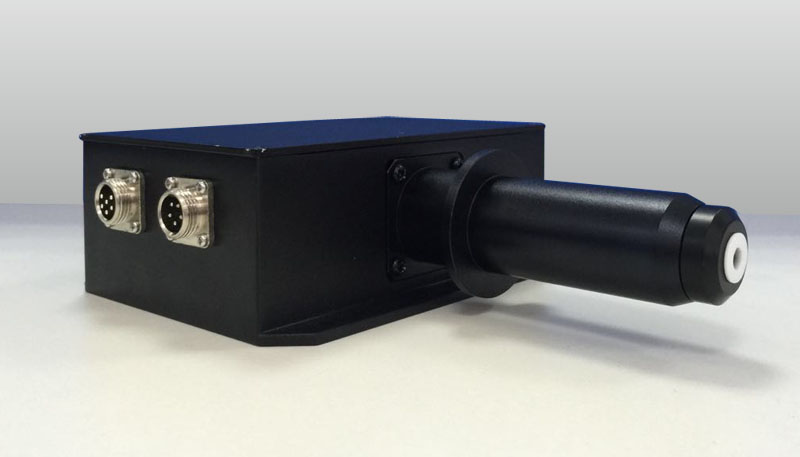

EDX 3600H Desktop XRF Spectrometer

High-Precision Alloy Analysis Desktop XRF with Si-Pin Detector and SNE Technology

Skyray Instruments specializes in the R&D, manufacturing and sales of analytical and measuring instruments in Spectroscopy, Chromatography and Mass Spectroscopy fields. Our Products include X-ray Fluorescence Spectrometry, Atomic Absorption Spectrometry, Gas Chromatography, Inductively Coupled Plasma Spectrometry, Mass Spectrometry and many others. With advanced research and development team Skyray has been providing customers around the world with reliable and affordable Scientific Instruments for more than 20 years

Skyray Instruments specializes in the R&D, manufacturing and sales of analytical and measuring instruments in Spectroscopy, Chromatography and Mass Spectroscopy fields. Our Products include X-ray Fluorescence Spectrometry, Atomic Absorption Spectrometry, Gas Chromatography, Inductively Coupled Plasma Spectrometry, Mass Spectrometry and many others. With advanced research and development team Skyray has been providing customers around the world with reliable and affordable Scientific Instruments for more than 20 years